Reliable temperature measurement is dependent on several factors that, more or less, inexorably lead to measurement errors. In this article we discuss the common causes of measurement errors in thermocouple thermometry.

Key causes of measurement errors in temperature measurement include:

Thermal Shunting

A temperature sensor conducts heat, which gives what is referred to as thermal shunting. This problem is particularly spotted when temperature is measured on surfaces. The greater the temperature difference, the greater quantity of heat is drawn out of the body of the sensor.

There is a sharp drop in temperature at the point where the sensor protrudes from the object to be measured. This is caused by a load being imposed on the object to be measured. The temperature drop is highest when the object to be measured is a poor conductor of heat (low thermal conductivity). To overcome this measurement issue, the point at which the sensor leaves the body to be measured must be at a proper distance from the measuring junction.

Inadequate Contact between Sensor & Measurement Object

Surface mounted sensors are not only specifically sensitive to thermal shunting, but also to errors associated with an inadequate contact between the sensor and the measurement object. Take a case of a spherical sensor which is placed in contact with a flat surface surrounded by the air. Only a fraction of the circumference of the sensor will be in contact with the object to be measured, while the rest of the sensor is exposed to the temperature of the air. Hence it is essential that maximum possible contact surface be achieved between the sensor and the object to be measured, and/or that the sensor is thermally insulated from the surrounding.

The effects from adjacent hot or cold surfaces are particularly precarious as thermal radiation can affect the sensor temperature over relatively vast distances

Find out more about: Fingertip Pulse Oximeter Blood Oxygen Saturation Monitor

Temperature Gradients and Thermal Conduction

Heat losses through the probe typically happen when a sensor connects a warm zone with a colder one, especially if the sensor is the easiest path for the transfer of heat. Heat is conducted away from the object being measured to the probe. The heat flux gives a temperature drop and the sensor measures a lower temperature than the true value. Such losses can be effectively countered if we ensure that the thermal conductivity in the object and across the probe tip is much higher than it is along the sensor. That is to say, more heat can be transferred to the sensor than conducted away by the sensor sheath.

Material Defects and Ageing

Every type of thermocouple is subjected to varying degrees of wear and ageing depending on the environments in which it is utilized. It is therefore crucial that all types of sensors are inspected and calibrated on regular basis.

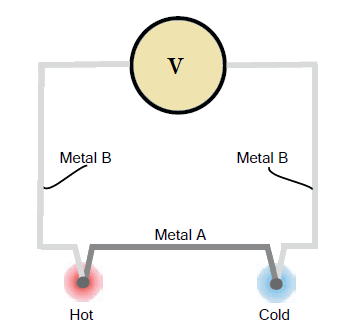

Connection Errors

Common connection errors that may cause measurement errors include:

Open Circuit/Circuit Break

A sensor wire that has fractured, coming adrift or is making a poor contact with the instrument may lead to open circuit. Advanced instruments often trigger an alarm, for instance, by displaying Open on the display unit.

Short Circuit

If the insulation has broken down and a short circuit occurs, a new measuring junction is created. The instrument will then display the temperature at the short circuit point instead of at the tip of the probe. At times it may be hard to detect this type of measurement error.

Reversed Polarity of Entire Measuring Circuit

If the polarity has been reversed, the instrument will also operate in reverse, in other words, a temperature increase will be recorded as a temperature decrease.

Reversed Polarity within the Measuring Circuit

The extension lead must have the same polarity as the thermocouple wires. If the polarity of the thermocouple element is reversed, opposing voltages occurs. The reading obtained will then be twice the temperature in the terminal head minus the temperature at the measuring junction.

Double Reversed Polarity

If the polarity of the extension lead has been reversed at both ends, the temperature at both ends will affect the output signal. The reading will be the temperature at the measuring junction less twice the temperature difference between the terminal head and the reference junction.

Response Time

The response time is defined as the time required for the sensor to reach some fraction of a stepwise temperature change of the surrounding, often 90%. The response time is connected to the sensor and its surrounding and not the sensor itself.

Some key factors affecting the response time of a sensor in contact with a body or medium include the following:

- The heat capacity of the sensor – the greater heat capacity and mass, the longer the response time.

- The heat transfer in the materials – air gaps and insulation, for instance, reduce the heat transfer.

- The contact surface between the sensor and the body or medium to be measured.

The response time can change over time, it can become shorter, if for instance, the junction of a sheathed probe is moved closer to the sheath or longer if for example, glue become brittle and porous and thereby gets different heat transfer properties.

Electromagnetic Interference

Thermocouples like many other measurement sensors can be affected by electromagnetic interference causing measurement errors.

Measurement errors can arise due to direct effects, for instance, induced current in the thermocouple wires. Recall that 1 °C corresponds to ~50 µV for some typical thermocouples. Furthermore, the small currents can give significant measurement errors. Induced currents can also heat the wires and the measurement junction, leading to a high temperature reading. Indirect disturbances can arise, for instance, if the inserted probe disturbs the EM field. Such indirect effects affect both the metallic probes material and plastics.

Related articles:

- Types of Transducers used in Biomedical Measurement Applications

- The Principle of Temporal Artery Thermometer

- Micrometer and Nanometer Biomedical Sensing Applications

- What is a Biosensor?

- Types of Bioelectrodes

Leave a Reply

You must be logged in to post a comment.