Pneumotachometers are instruments that measure the instantaneous rate of volume flow of respired gases. They can be broadly classified into two types based on the principle of operation:

- Hot-wire anemometer – it employs a small heated element in the pathway of the gas flow. The current required to maintain the element at a constant temperature is measured and it increases proportionally to the gas flow that cools the element.

- Differential manometer – it has a small resistance, which allows flow but cause a pressure drop. This change in pressure is measured by a differential pressure transducer, which outputs a signal proportional to the flow according to the Poiseuille law, assuming that the flow is laminar. The unit is heated to maintain it at 37° C to prevent condensation of water vapour from the expired breath.

The pneumotachometer is normally used to measure parameters relating to pulmonary function such as forced expiratory volume (FEV), maximum mid-expiratory volume, & peak flow and to generate flow-volume drops. While these instruments directly measure only volume flow, they can be used to derive absolute volume changes of the lung (spirometry) by electronically integrating the flow signal.

Traditional mechanical spirometers through more accurate than pneumotachometers have limitations due to their mechanical inertia, hysteresis, and carbon dioxide build-up. On the other hand, pneumotachometers are rather non-obstructive to the patient, and this makes them appropriate for long-term monitoring of patients with respiratory difficulties.

A basic requirement of pneumotachometers is that they should present a minimum resistance to breathing. A bias flow in the flow head is sometimes introduced to prevent rebreathing of expired air. A good zero stability is a precondition of pneumotachometers to prevent false integration during the volume measurements.

The common types of pneumotachometers are:

- Fleisch pneumotachometer

- Venturi-type pneumotachometer

- Turbine-type pneumotachometer

Fleisch Pneumotachometer

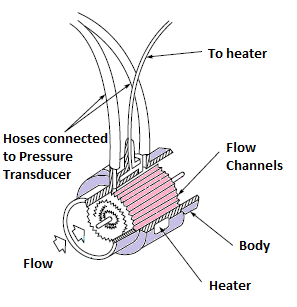

This type of flow transducer is commonly employed in respiratory studies. It is made by rolling a sheet of thin corrugated metal with a plain strip of metal and inserting this core within a metal cover.

Find out more about: Fingertip Pulse Oximeter Blood Oxygen Saturation Monitor

Therefore, these transducers are resistance elements consisting of small, parallel metal channels. This construction helps to maintain a laminar flow at much higher flow rates than would be possible for a covering of similar area. In case of laminar flow, the pressure drop across the element is directly proportional to the flow rate of gas passing through it.

The output of the flow transducer appears as a differential pressure. To convert this pressure into an electrical signal, a second transducer is needed. A capacitance type pressure transducer is employed in such applications because they are more stable and less vibration-sensitive than resistive or inductive type transducers.

At high flow rates, turbulence develops in the hose leading to the pneumotach transducer and its response tends to become non-linear. This limits the usable range of the transducer.

The calibration of pneumotachograph head in terms of volume flow rate can be done by passing known gas flows through it. The flow can be produced by a compressor and measured with a rotameter type gas flowmeter.

Nearly all respiratory parameters are reported in BTPS conditions (body temperature, ambient pressure, saturated with water vapour). This is the condition of air in the lungs and the mouth. To avert condensation and maintain gas under these conditions, the temperature of the pneumotach is maintained at 37 °C. The heater that warms the pneumotach is electrically isolated from the metal case for patient safety, and is encapsulated so that the entire unit may be immersed in liquid for sterilization. The thermistor that senses the temperature and controls the heater through a proportional controller is buried in the metal case.

Related: Key Considerations in Respiratory Measurements & Instrumentation Involved

Venturi-type Pneumotachometers

This type of pneumotachometers works in same way as the Fleisch pneumotachometers but has a venturi throat for the linear resistance element. The resulting pressure drop is proportional to the square of volume flow. They have an open geometry; hence they are less prone to problems of liquid collection. Their main shortcomings are the non-linearity of calibration and the requirement for laminar flow.

Turbine-type Pneumotachometers

The operation of this type of pneumotachometers involves air flowing through a transducer that rotates a very low mass turbine blade mounted on jewel bearings. The rotation of the turbine blade interrupts the light beam of a light emitting diode (LED). The interrupted light beam falls on a phototransistor, which produces a sequence of pulses, which are processed and accumulated to a respond to an accumulated volume in liters.

A unique feature of this transducer is a bias air flow that is applied to the turbine blades from a pump. This flow keeps the blades in a constant motion without even the sample flow through it. This permits measurement of sample air flow in the range of 3 to 600 liters/min in the most linear range of the volume transducer by overcoming much of the rotational inertia of the turbine. The ‘’ZERO’’ control of the volume transducer adjusts the bias air flow to produce a sequence of clock pulses of exactly the same frequency as those generated by the crystal oscillator.

You can also read:

- Types of Oximeters

- The Process of Oximetry in Biomedical Measurements

- Key factors that affect or limit Biomedical Measurements

Leave a Reply

You must be logged in to post a comment.