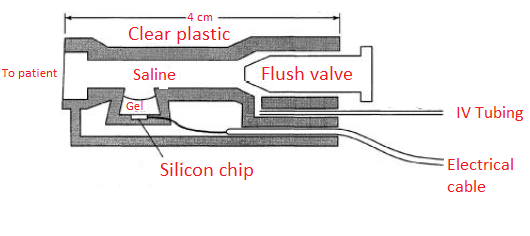

Disposable blood pressure sensors are made of clear plastic so that air bubbles are easily seen

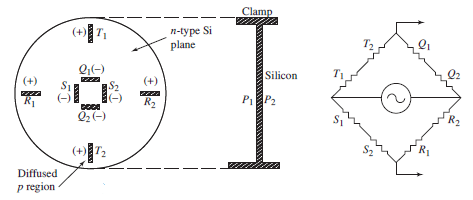

Saline flows from an intravenous (IV) bag through the clear IV tubing and the sensor to the patient. This is used to flush out blood out of the tip of the indwelling catheter to prevent clotting. A lever can open or close the flush valve. The silicon chip has a silicon diaphragm with a four-resistor Wheatstone bridge diffused into it as shown in Figure (b) below.

The silicon chip’s electrical connections are protected from the saline by a compliant silicone elastomer gel, which also provides electrical isolation. This prevents electric shock from the sensor to the patient and prevents destructive currents during defibrillation from the patient to the silicon chip.

This integrated pressure sensor has an advantage in that it can be fabricated by using a silicon substrate for the structural member of the diaphragm. The gauges are diffused directly on the diaphragm. When pressure is applied to the diaphragm, a radial stress component occurs at the edge. The sign of this component is opposite to that of the tangential stress component near the center.

The placement of the eight diffused strain gauges units as illustrated in Figure (b) above, gives high sensitivity and good temperature compensation.

Silicon strain gauge pressure sensors, can be placed on the tip of catheter and inserted directly into the blood resulting in more accurate measurements and faster response times.

Find out more about: Fingertip Pulse Oximeter Blood Oxygen Saturation Monitor

Related: Blood Pressure Measurement

Leave a Reply

You must be logged in to post a comment.